|

H.K.Industries Vacuum Technologist |

|

| Get A Quote | Application | Client List | Contact us |

Our engineers, scientists and designers are capable of tackling the most complex and difficult problems. Scrubbers are custom designed to meet your specific performance requirements.

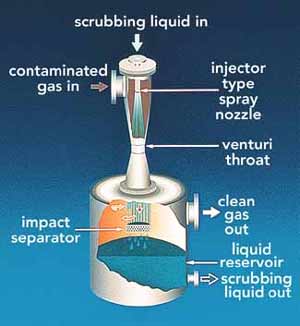

| Venturi scrubbers |